Committed to Clean, Sustainable Personal Care

Roundtable for Sustainable Palm Oil

Bradford joined RSPO as a member in 2016. We are committed to providing Segregated RSPO palm oil, the highest level of RSPO certification. We can trace the palm oil from the exact plantation directly to our manufacturing facility in West Warwick, RI. The family-owned plantation has invested in the local rural community by building a school and a state-of-the-art medical clinic. Their work was recently recognized by the World Economic Forum in 2021 for Excellence in Social Responsibility.

Learn More About RSPO

The Global Shea Alliance

Bradford has committed to buying our shea butter through the Global Shea Alliance. The shea communities we support hand process the shea nuts into shea butter, thereby receiving more value for the shea nuts they collect. We have also committed to creating formulations that utilize large amounts of shea butter because of its moisturizing properties and sustainable sourcing. Bradford traveled to Ghana with a camera crew to promote the women shea collectors and their positive impact on the community.

The Global Shea Alliance (GSA) was founded in 2011 on a foundation of empowering African communities one woman at a time. The GSA designs, develops and delivers strategies that drive a globally competitive and sustainable shea industry. In 2019, we traveled to Ghana to visit the communities that process our shea butter using a traditional hand-crafted method. Our commitment to sourcing from the Global Shea Alliance and these villages not only provides additional income for the families, but it also helps to empower the women who are central to the process.

Learn More About the Global Shea Alliance

Clean Ingredients Lists. Sustainable Packaging.

Committed to Clean ® Initiative

We maintain a comprehensive approach to responsible manufacturing in the areas of product, packaging, supply chain, energy, waste, and emissions.

Through the Committed to Clean® initiative, Bradford has significantly reduced material waste. Bradford improved our environmental impact in the following areas:

- 25% decrease in manufacturing carbon dioxide emissions since 2019

- Recycled 137 tons of recyclable waste in 2021

- Over 2% decrease in energy usage overall since 2019

- 72% increase in total recycled waste since 2016

Packaging

Bradford is committed to recycling, reducing packaging waste, and sourcing more environmentally friendly alternatives to conventional packaging. Through the Committed to Clean® initiative, we have made improvements in the following areas:

- Developed products that contain little or no water to reduce the amount of packaging required.

- Partnered with multiple zero-carbon and reduced-carbon footprint packaging production facilities

- Sourced FSC and SFI certified board

- Sourced Post-Consumer Waste certified packaging

- Sourced How 2 Recycle single-stream compliant packaging

Zero Waste

Over the years, Bradford moved toward zero waste manufacturing by donating all soap scraps to worldwide health and hygiene initiatives through World Vision and Eco-Soap Bank. On average, Bradford donates over 200 tons of soap scraps yearly (roughly equivalent to 2 million bars).

The donations have directly helped some of the world’s most vulnerable communities, including Somalia, Zambia, Burundi, and Cambodia, where the women reform the soap into bars. The soap provides access to hygiene products, additional income, women’s empowerment, decreases lines at health clinics, and helps prevent COVID-19 transmission.

Clean Ingredients

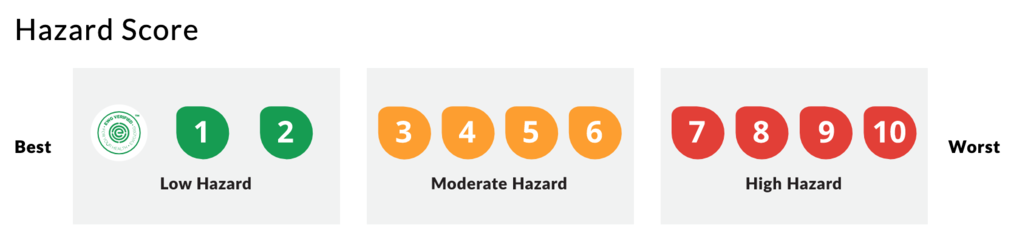

We strive to use clean ingredients with Environmental Working Group (EWG) ratings of 3 or less, and limited added preservatives.

The mission behind maintaining low EWG ratings is to protect people and the environment through the use of safe ingredients.

Learn More About EWG Ratings

Water Conservation

Bradford leveraged our expertise in solid cleansing to develop a broad range of personal care products that contain little or no water.

The products we’ve developed with little to no water include shampoo bars, facial cleansing sticks, moisturizing sticks, natural deodorants, and shave products. Using less water in the products reduces packaging, minimizes product carbon footprint, and uses fewer preservatives. It also conserves water, our greatest natural resource.